Allows you to test, test and configure the manufactured equipment running on gas fuel for compliance with the requirements of regulatory and design documentation.

One of the largest testing centers in the Siberian Federal District.

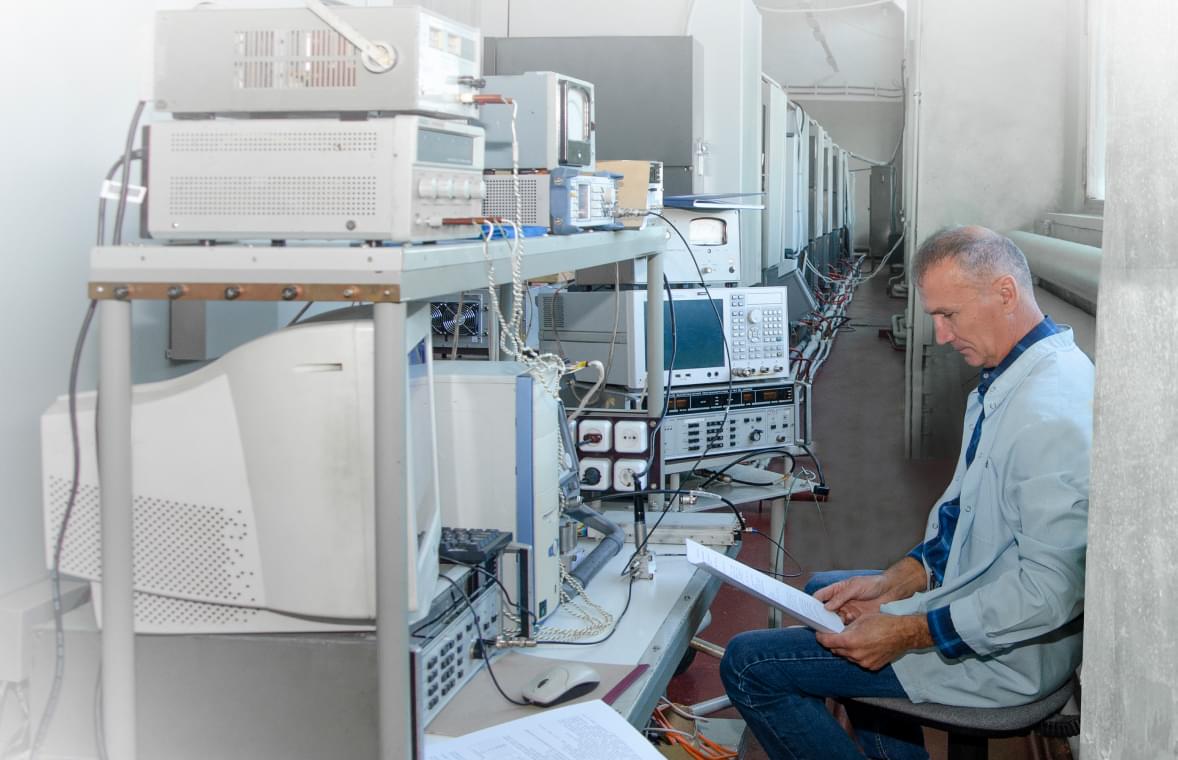

The RIC has certificates of accreditation within the framework of the Ministry of Defense of the Russian Federation, the Russian Maritime and River Registers of Shipping, is equipped with the necessary measuring and testing equipment that allows certification tests of all types (in particular for electromagnetic compatibility, fire and electrical safety, checking the degree of protection provided by the shells, checking the functional characteristics of electrical equipment), mechanical and climatic impacts.

It is equipped with the necessary equipment, tooling and tools to ensure high-quality assembly, equipment configuration, and acceptance tests that confirm the equipment's operability and compliance with design documentation and technical parameters, as well as electrical and fire safety requirements in accordance with the product specifications.

The complex is a dynamically developing division in the structure of ONIP, in which research, development and production of the element base of piezo-quartz technology, acoustic and microelectronic technology, micromodules of various functional purposes, sources and secondary power supply systems, VLSI class «System on a chip» are conducted.

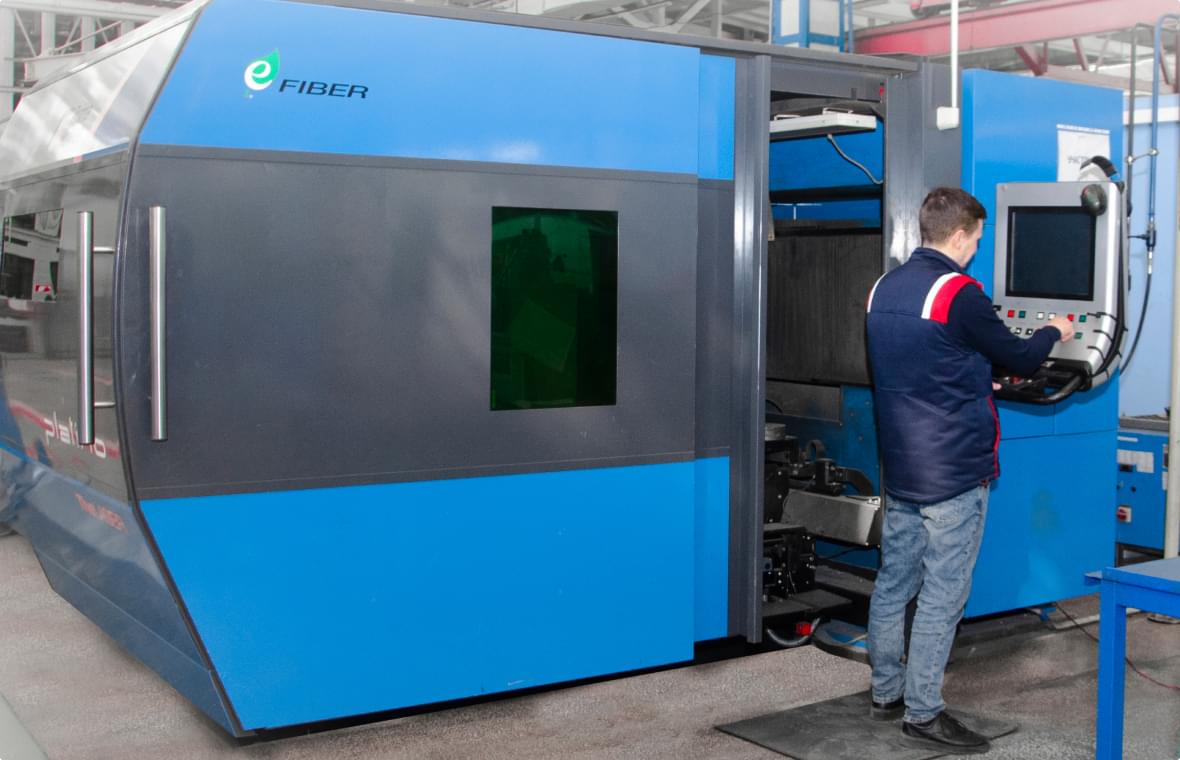

The laboratory conducts:

- accelerated production preparation

- development of design and technological solutions without the participation of the main production

- quick launch of a small series of parts made of silicones and plastics

- 3D printing of highly complex parts directly from a digital model

Equipped with equipment that allows you to produce:

- drying of lumber

- mechanical processing of the material, including turning and milling operations on CNC machines

- processing of valuable wood species

- cutting chipboard, chipboard, fiberboard

- carpentry boards

- joinery of any complexity

- cabinet furniture

Equipped with equipment for the manufacture of products from thermoplastic plastics by cast under by pressure, as well as by pressing made of press materials and rubber compounds, including reinforced ones.

Allows the production of parts, as well as elements of parts of various depths and transparency, decorative and functional items made of thermoplastic polymers and elastomers: impact-resistant polystyrene, ABS plastic, polycarbonate, HDPE and PP.

Assembly and assembly production includes specialized workshops with sections of assembly, adjustment of products and assemblies with dedicated sections installation.

The foundry produces:

- parts made of ferrous and non-ferrous metals by smelted models

- thin-walled parts of complex configuration of high precision casting with high quality surfaces

Modern automated and universal equipment is used in production, providing a closed cycle of manufacturing parts with a given degree of accuracy of executive dimensions from various types of steels and structural alloys.

The production of printed circuit boards is equipped with a complex of modern equipment and allows you to design, produce and produce high-quality printed circuit boards of the 5th accuracy class.

Electroplating and painting production allows:

- to cover parts made of steel, aluminum alloys, copper and its alloys with various types of coatings

- paint with liquid paints and varnishes with thermal radiation drying

- paint large-sized parts with cold-drying enamels and powder coating

Assembly and assembly production includes specialized workshops with assembly sites, adjustment of products and assemblies with dedicated installation sites.

Has qualified specialists-developers who apply progressive design methods. Constantly carries out measures to improve the efficiency and competitiveness of developments, reduce design time.